Production & Equipment

Technology - Innovation - Services

Typical Creation Process - Special Custom Fabrications

Everfit Technology CO., LTD. (EFT) is a vacuum component , vacuum fitting, processing equipment and system provider with 36 years of experience; our stainless steel vacuum component is applied in dynamic areas containing semi-conductors, pharmaceuticals, bio-technology, food processing and structural engineering to provide process controls for solid and fluid materials. We assure stable control processes and cost effective production flows in all important aspects.

EFT has been dedicated to providing world-class stainless steel vacuum components and mechanical equipment by procuring stainless steel materials from the largest steel companies in Taiwan; manufacturing stainless steel vacuum fittings that have the quality equivalent to international companies such as Alfa Laval, Gemü and EUROBINOX; implementing mold design and fabrication sector to cut down on the cost and increase product quality; applying 100% test to deliver great customer satisfaction; building cleanroom for stainless steel vacuum components and valves that require strict hygiene.

We have a 5,500 square meter plant that is capable of performing mold design and manufacturing, heat treatment, casting, forging, plating, drilling, milling, CNC machining, cleaning, welding, assembling, and packing.

We have a vast selection of stainless steel vacuum components for your control systems including:

- Stainless steel Seat valves

- Diaphragm valves (or membrane valves)

- #3Tank Valves

- Butterfly valve actuators

- Butterfly Valves

- Non Return Valves

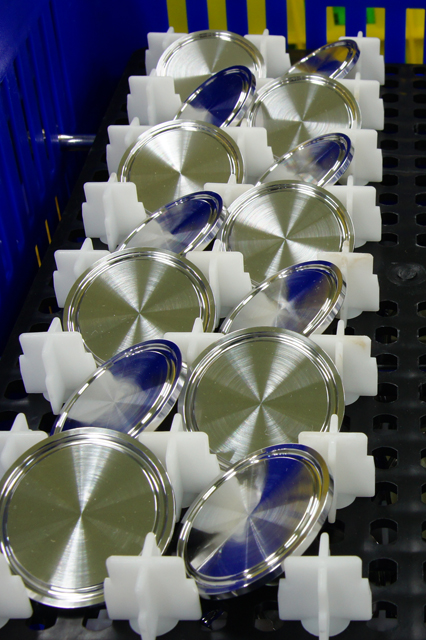

- Sight Glasses (sight flow indicator)

- Sample Cock Valves

- Safety and Relief Valves

- Filling Valves

- Ball Valves

- Clamp / Ferrule

- Union

- Stainless Steel Pipe Clamps / Stainless Steel Pipe Ferrules

- Stainless Steel Pipe Ferrule Adapters

- Stainless Steel Union Parts

- Stainless Steel Pipe Fittings ( ASME BPE )

- Stainless Steel Sanitary Tubes (TEE, Reducer, Cross, Bend)

Test Equipment:

- Innov-X Stsyem Handheld EDXRF Analyzer

- Mitutoyo Contracer Contour Measuring Instrument

- Optical Comparator

Manufacturing Process:

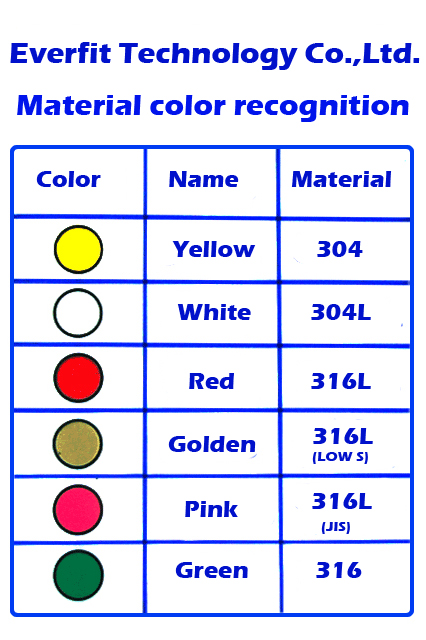

- We often have a sufficient stock of raw materials to strain the customer demand, with the test gun purchase (handheld EDXRF, analyzer to) to examine the properties of the material. And use color to distinguish the effect of material to achieve control.

- We have developed the ability to mold to the diverse needs of customers.

- We have more than five sawing machines, can provide a lot of material handling. Sawing machine automatically and immediately cleaning materials to reduce the dependence of the impurity in the material, to allow subsequent processing smoothly..

- High-frequency induction hardening machine for hot forging

- Gas burner for hot forging

- 200, 300 and 800 tons stamping pressing machines to handle large quantity stainless steel equipment

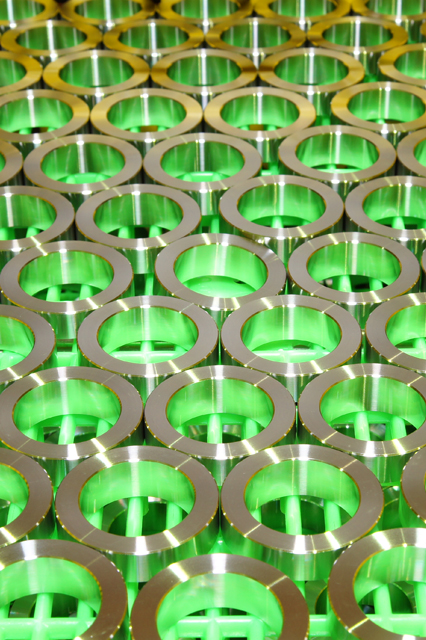

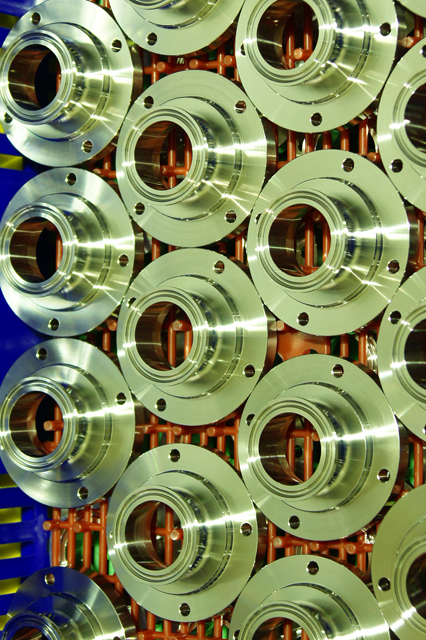

- 18 CNC lathe machines, 2 CNC milling machines with 4 CNC lathe machine blade change engineers, CNC lathe machine and milling machine for stainless steel valves, pipes and fittings:

- Onsite inspection every two hours

- Ultrasonic And RO Water Cleaning Process

- Gauge and measuring tools for stainless steel parts

- • Mitutoyo Contracer Contour Measuring Instrument; Optical Comparator)

- Stainless steel Part welding

- Stainless Steel Part Electroplating

- Stainless Steel Part Polishing

- Stainless Steel Part Assembling

- Stainless Steel Part Testing

- Stainless Steel Part Labeling

- Stainless Steel Part Packaging And Shipping

Hot Products

Hot

Hot

Vacuum Components

Hot

Hot

Vacuum Components

EFT provide flanges not only KF, ISO but also CF standard specification . We have...

Read More Hot

Hot

Sanitary Valve

Hot

Hot

Sanitary Valve

EFT can offer variety sanitary valve with food grade and get 3A certificate . Our diaphragm...

Read More Hot

Hot

Sanitary Fittings

Hot

Hot

Sanitary Fittings

EFT owns forging factory with the objective of building a professional image and providing...

Read More Hot

Hot

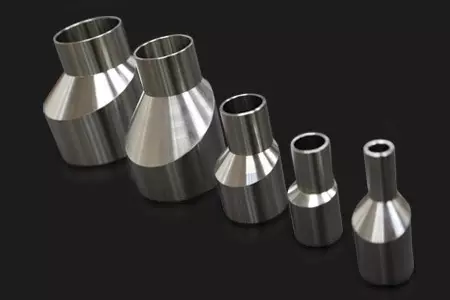

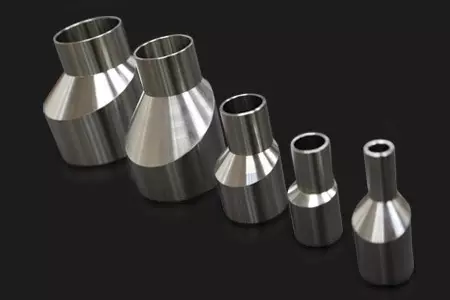

BPE Reducer

Hot

Hot

BPE Reducer

EFT can help with general issues or individual needs. EFT offers unique raw material...

Read More