Sanitary Valve

Sanitary Valve

Diaphragm valve

Diaphragm valve

EFT has developed a line of valve bodies that help address the needs of the Bioprocessing and Pharmaceutical industries for high quality, welded process systems. By providing valve bodies with controlled sulfur SS316L stainless steel material and weld tangents long enough to accept the most common orbital weld heads in the industry, we have eliminated two of the most common concerns in valve-to-tube welding known today.Automatic welding of 316L process components is greatly affected by the sulfur content of the mating process components. A disparity of sulfur content can result in reduced orbital weld quality and potentially incomplete fusion of the mating components. By controlling valve body sulfur content to the same chemistry as that required for ASME BPE fittings, welding problems due to material chemistry differences will be greatly reduced. The EFT of valve bodies fully complies with the controlled sulfur requirements for chemical composition of SS316L material, set by the ASME Bioprocessing Equipment Standard 2002. By increasing the valve weld end tangent lengths to the values required for ASME BPE fittings, we made the valve body compatible with virtually any orbital weld head utilized in the industry. Special offset or narrow heads are no longer required to weld a valve into a process system.

The original seat valve

The original seat valve

Ideal for uninterrupted production in a broad range of hygiene-critical applications, Unique single seat valves are pneumatic seat valves used to shut off or change product flow. EFT Seat valves are the extremely reliable all-rounders in the valve world. Our range includes on/off and control valves in stainless steel, with a stainless steel bonnet or a lightweight plastic actuator. They are available with a threaded or Tri-clamp connection, actuation is either pneumatically or motor-driven and they can be supplied with a flanged body. EFT Seat valves has very flexible design which meets sanitary requirements, and is mainly used in pipeline systems without contaminant or mixture. As a modern and widely-used valve, it is mainly used in the wine brewing, dairy, beverage, and pharmaceutical industries.EFT Seat valves is remotely operated by means of compressed air. By controlling the relative position of valve plug, it makes the valve open or closed, or changes the flow direction of media. EFT Seat valves is equipped with our smart controller, which not only remote controls the single-seat valve, but can also perform real-time monitoring of the valve working conditions and timely feedback of signals. It can also be equipped with the position sensor only.

The original manual seat valve

The original manual seat valve

Ideal for uninterrupted production in a broad range of hygiene-critical applications, Unique single seat valves are pneumatic seat valves used to shut off or change product flow. EFT Seat valves are the extremely reliable all-rounders in the valve world. Our range includes on/off and control valves in stainless steel, with a stainless steel bonnet or a lightweight plastic actuator. They are available with a threaded or Tri-clamp connection, actuation is either pneumatically or motor-driven and they can be supplied with a flanged body. EFT Seat valves has very flexible design which meets sanitary requirements, and is mainly used in pipeline systems without contaminant or mixture. As a modern and widely-used valve, it is mainly used in the wine brewing, dairy, beverage, and pharmaceutical industries.EFT Seat valves is remotely operated by means of compressed air. By controlling the relative position of valve plug, it makes the valve open or closed, or changes the flow direction of media. EFT Seat valves is equipped with our smart controller, which not only remote controls the single-seat valve, but can also perform real-time monitoring of the valve working conditions and timely feedback of signals. It can also be equipped with the position sensor only.

The original manual tank valve

The original manual tank valve

EFT is a pneumatic seat valve with sanitary and flexible design. Based on the mature single seat valve design platform, few and simple moving components make the valve reliable, and reduce the maintenance cost. FS3 tank bottom valve is used to close or open the pipe leading to the tank. It is widely used in brewing, dairy, beverage, and pharmaceutical industries.EFT tank bottom valve is remote controlled by compressed air, which consists of one valve and one tank bottom flange. In order to reduce the abrasion of seal components, the compression to seal components is performed through touching between metals.The modular design of the valve in connection with the radial seal to the tank now make it possible to close reliably against higher pressures than before. The reliability of the process is also enhanced: the balancer fitted in the closing direction prevents the double disk from closing too fast, thus reducing the risk of pressure hammers.

Actuator

Actuator

EFT took great care in making them industry appropriate, operator friendly and yet sturdy enough to withstand some pretty rough treatment. We made sure that our pneumatic actuators are not spring loaded, they all are machined from 304 Stainless Steel and are designed to withstand some dings and drops. All actuators have a position indicating shaft that extends when the valve is open (for visual confirmation of valve position) and contain as few o-rings and seals as possible which require very simple maintenance on an annual basis. Additionally, to prevent any galling, we machine all our actuator bodies out of 304 Stainless Steel, All EFT actuators meet 3A requirements and can withstand operating pressure of 250 psi and operating temperature of 135° C (or 275° F).

Butterfly valve

Butterfly valve

Butterfly valves are relatively straightforward on/off routing valves with a substantial opening area and low flow resistance. Where hygiene standards are important, these are ideal for use with low and medium-viscosity liquids. EFT butterfly valves have proven their worth in process plants with different types of processes. EFT not only offers seat valves but also a butterfly valve series which fully satisfies increasingly higher market demands with respect to functionality, safety and cost-effectiveness. EFT butterfly valves are versatile and ensure smooth production processes, whether in production, cleaning or energy management applications in the beverage and food industries, in breweries, in the dairy processing industry or in the pharmaceutical, biotechnological, fine chemicals, cosmetics and health care sectors. What counts are the quality of the final product and the efficiency of the production line. EFT butterfly valves are pointing the way – the development is based on the latest findings in process technology – in compliance with international standards.

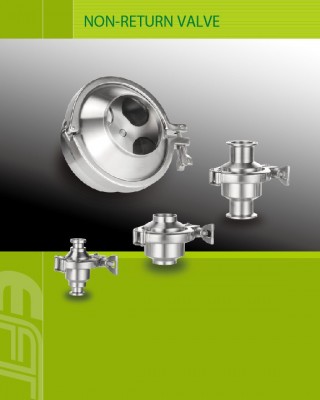

Non-return valve

Non-return valve

Stainless steel non-return valve for reverse flow protection. Ideal for pump outlets, general process, filling lines and backflow prevention service. EFT non-return valves specially designed for use in stainless steel pipe installations, EFT non-return valves prevent the reverse flow of fluids. Widely used in various processes throughout the sanitary industry, these standard non-return valves are safe and highly reliable. EFT non-return valve design is based on the application of an external magnetic field to close the shutter, thus interrupting the backflow inside a pipe. This innovative principle guarantees a degree of reliability which the classic spring system cannot provide.

Sight glass

Sight glass

EFT 's sight glasses are designed for visual inspection of media inside pipes and/or inspection of pigs in product recovery systems. The Borosilicate glass inside the housing is fixed without any tension and does resists hard pressure and vibration shocks. EFT 's sight glasses are accurate gage glasses that permit direct distortion-free visual inspection of process conditions, products, liquid levels and cleaning inside vessels used in the dairy, food and beverage, personal care and biopharm industries.

Sample cock valve

Sample cock valve

The sample cock valve has a fixed handle and is manually operated. Samples are taken from the bottom outlet. In closed position after sampling, the cock drains out completely so that no product remains inside the cock.On tanks and pipework. The sample cock should be placed directly at the sampling place with minimum distance to the product. Mounting sockets in stainless steel AISI 316L for welding into tanks and pipework are available with material certificate. Maintenance the plug of the sample cock must be lubricated with foodgrade grease when the cock is included in CIP of vessel or pipeline. Hand tools may not be used on the sample cock.

Ball valve

Ball valve

Sanitary ball valves feature a full-bore design that enables full fluid flow with minimal pressure drop, making them ideal for handling viscous liquids or liquids containing particles in the food, beverage, chemical and pharmaceutical industries.

Hot Products

Hot

Hot

Vacuum Components

Hot

Hot

Vacuum Components

EFT provide flanges not only KF, ISO but also CF standard specification . We have...

Read More Hot

Hot

Sanitary Valve

Hot

Hot

Sanitary Valve

EFT can offer variety sanitary valve with food grade and get 3A certificate . Our diaphragm...

Read More Hot

Hot

Sanitary Fittings

Hot

Hot

Sanitary Fittings

EFT owns forging factory with the objective of building a professional image and providing...

Read More Hot

Hot

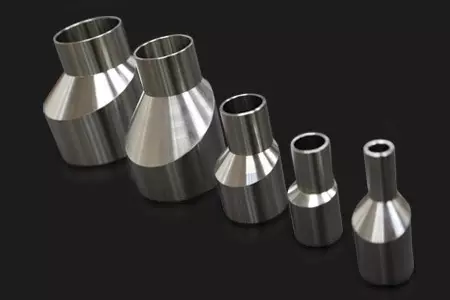

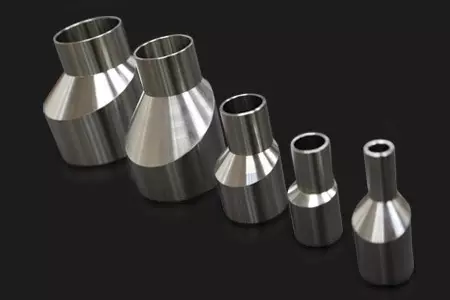

BPE Reducer

Hot

Hot

BPE Reducer

EFT can help with general issues or individual needs. EFT offers unique raw material...

Read More